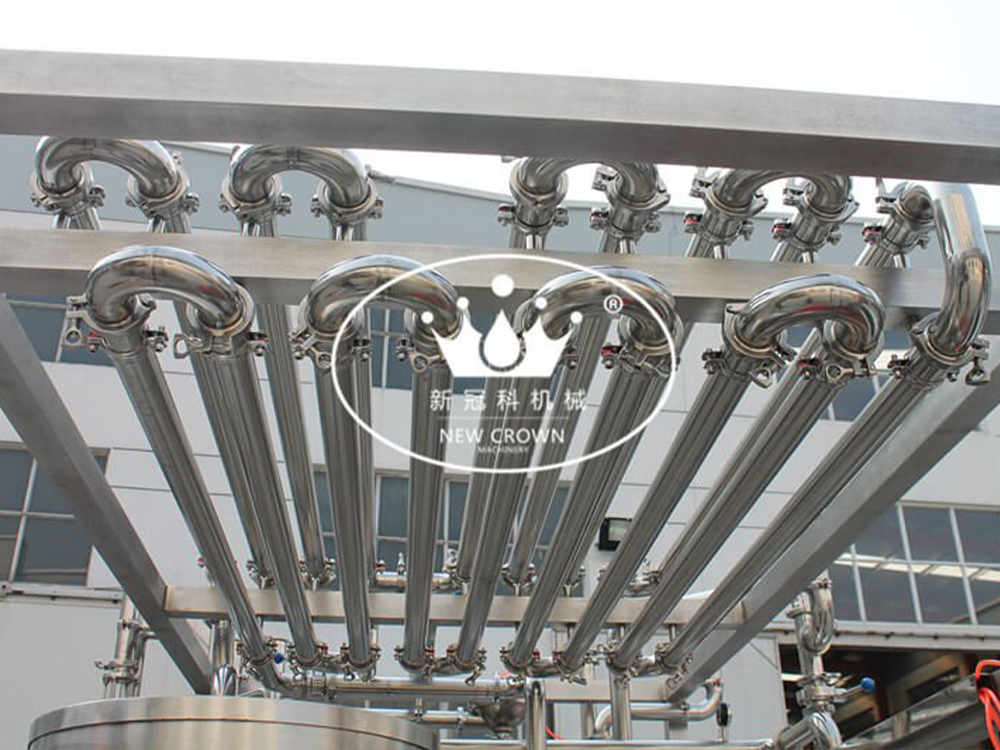

Plate type fast sterilizing HTST Pastuerizer

Plate type fast sterilizing HTST Pastuerizer is for liquid pre-treatment, fast sterilizing and pastuerizing.

Technical Specifications

| Model | Capacity (t/h) | Steam consumption (kg/h) | Steam pressure (bar) | Cold water flow (T/H | Electric power (kw) | Body size (L×W×H) | Weight (kg) | ube diameter(Φ) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Steam | Medium | ||||||||

| HE-BR0.1-DJ-1 | 1 | 40 | 5.0 | 2 | 2.8 | 1.6×1.4×1.8 | 820 | 25 | DN25 | 25 |

| HE-BR0.1-DJ-1.5 | 1.5 | 60 | 5.0 | 3 | 2.8 | 1.6×1.4×1.8 | 860 | 25 | DN25 | 25 |

| HE-BR0.1-DJ-2 | 2 | 80 | 5.0 | 4 | 3.0 | 1.6×1.4×1.8 | 890 | 38 | DN25 | 38 |

| HE-BR0.1-DJ-3 | 3 | 120 | 5.0 | 6 | 3.7 | 1.8×1.6×2.0 | 1030 | 38 | DN25 | 38 |

| HE-BR0.1-DJ-4 | 4 | 160 | 5.0 | 8 | 3.7 | 1.8×1.6×2.0 | 1100 | 38 | DN25 | 38 |

| HE-BR0.1-DJ-5 | 5 | 200 | 5.0 | 10 | 3.7 | 1.8×1.6×2.0 | 1170 | 38 | DN25 | 38 |

Description

Production description:

Plate type fast sterilizing HTST Pastuerizer is sterilization equipment specially designed for juice,tea drinks or similar liquid materials. It is the ideal equipment that material can extend the shelf life purpose through sterilizing and cooling. According to users’ different requirements to material heating, sterilization, heat preservation and cooling, to design various technical requirements for different flow assembly, meet the technological requirements and have all kinds of security protection measures and high temperature alarm, low temperature function of the back flow. At the same time, according to users’ requirements, corresponding configuration of high accuracy of the automatic control system.

Semi-automatic configuration: the whole process of operation is semi-automatically control. Operator can control the pumps, valves and back flow function on the control panel. By the temperature control PID to maintain the sterilization temperature. Sterilization temperature has a continuous record.

The plate HTST stands between the pasteurizer and the UHT, the production procedures are as following: 5℃→65℃(homogenization)→120℃(15S)→25℃/5℃.can be used for PET hot filling or roof shape filling sterilize.

Semi automatic control:

UK Spirax sarco steam pressure reduce valve, German Burkert or spirax sarco temperature control system, German Labom

temperature transducer, Anthone temperature recorder without paper, Italy hot water pump; Siemens LOGO control,

the precision of temperature control is ±0.5 degree.

Full automatic control:

UK Spirax sarco steam pressure reduce valve, German Burkert or spirax sarco temperature control system, German Labom

temperature transducer, Anthone temperature recorder without paper, Italy hot water pump; Siemens PLC Full-Auto control

with touch screen, the precision of temperature control is ±0.5 degree.

Advantages:

1. Heat transferring efficiently

2. Energy saving

3. Temperature controlling is more accuracy

4. No touching the liquid, more hygiene

5. Cleaning more easily

Applications:

Pulp Juice Bottle Filling Machine is mainly designed for filling hot temperature liquid with fruit piece into bottles; For example juice, tea drinks etc which are made of concentrate juice.

Packaging & Delivery:

All New crown Machines will be packed with high quality plastic film, then put into the wood box increase there is crash and damages.

FAQ:

1, When you can arrange the delivery after customers place the order ?

A: Normally production time is around 30-60days,the exactly depend on what kind of machine you ordered .

2, How long time for installation?

A: According your machines order,we will arrange one or two engineers to your factory,it will take about 1 to 2 weeks.

3, What kind payment be accepted by New crown?

A: We can accept L/C,West union,TT

4, How to install my machines when it arrives?how much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.Customer pay air tickets go and back,accommodation,food,and so on.USD 100/DAY/PERSON

Installation and maintenance:

The machines should have good maintenance twice for 6 months,and for installation, you can get the manual guide from Newcrown, or we can sent our engineers to help you.

Request A Quote

Keep in touch

Fill in your details and we’ll get back to you in no time.