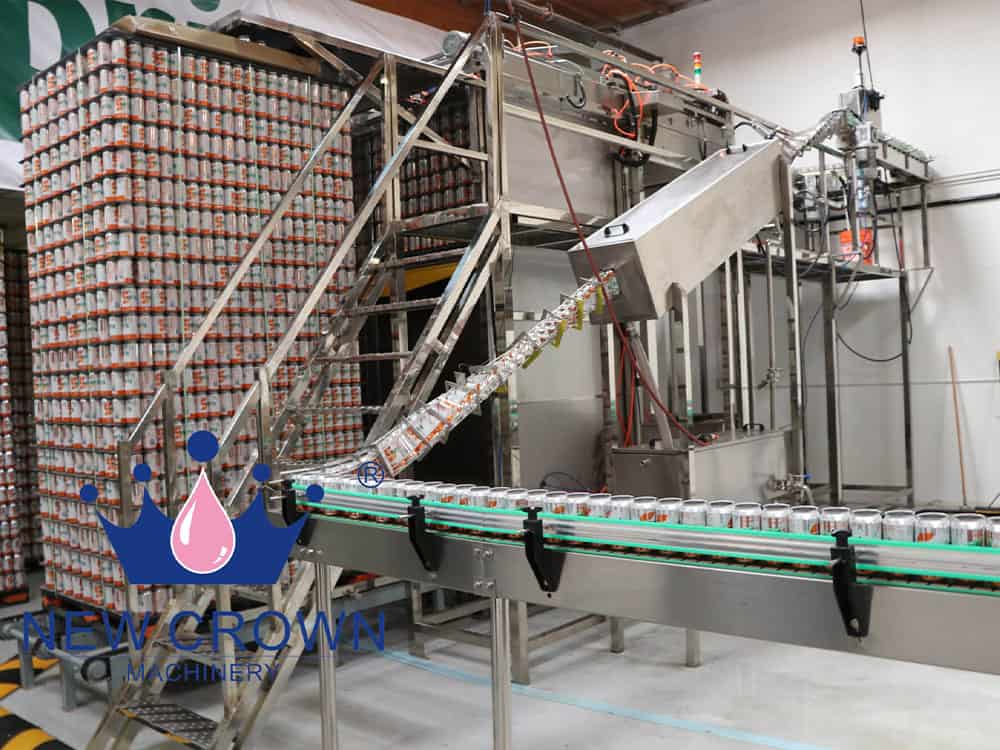

Complete Beer Canning Filling Machine

We offer turn-key plant for complete beer line with different capacities. The flow chart will be: Automatic empty can de-palletizer—Automatic can washer—Automatic beer can filling-seaming machine—Pasteurizer tunnel—Auto can dryer—Can turning device—Date printer—Can turning device—Automatic PE film shrink wrapping machine

Technical Specifications

Description

Product Description:

Automatic empty can de-palletizer

Automatic empty can de-palletizer is mainly suitable for de-stacking empty cans, it will be stacked on the pallet empty cans, bottom-up layers of ascension and layered pushed to the path of the conveyor chain, with empty cans of spray cans machine use, replace artificial row of cans and traditional empty cans of unloading tank machine, can save a lot of artificial, increase production capacity.

Automatic can washer

This can washer is used for washing empty cans after de-palletizing.

Automatic beer can filling-seaming machine

It is used for filling and seaming for beer and gas drink packed in aluminum cans and also other cans; The cans can be connected with can washer with belt conveyor.

Auto can dryer

This machine is mainly used for the drying outside of bottles before or after the processing that the machine requires the bottle without water outside.

Can turning device

This is to installed on the conveyor line to turn down the cans, and print date under the bottom of cans.

Inkjet Date printer

This printer is used for printing information on bottom of cans. There are ink or laser type printer.

Automatic PE film shrink wrapping machine

This machine is used to shrink products such as dozens of cans, bottles, carton box etc. Can finish the shrinking in a short time even for a big product and it is smooth and compact after shrinking.

Application:

Complete Beer Canning Filling Machine is for manufacturer start from Automatic empty can de-palletizer to Automatic PE film shrink wrapping machine,

Packaging & Delivery:

All New crown Machines will be packed with high quality plastic film, then put into the wood box increase there is crash and damages.

FAQ:

1, When you can arrange the delivery after customers place the order ?

A: Normally production time is around 30-60days,the exactly depend on what kind of machine you ordered .

2, How long time for installation?

A: According your machines order,we will arrange one or two engineers to your factory,it will take about 1 to 2 weeks.

3, What kind payment be accepted by New crown?

A: We can accept L/C,West union,TT

4, How to install my machines when it arrives?how much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.Customer pay air tickets go and back,accommodation,food,and so on.USD 100/DAY/PERSON

Installation and maintenance:

The machines should have good maintenance twice for 6 months,and for installation, you can get the manual guide from Newcrown, or we can sent our engineers to help you.

Request A Quote

Keep in touch

Fill in your details and we’ll get back to you in no time.