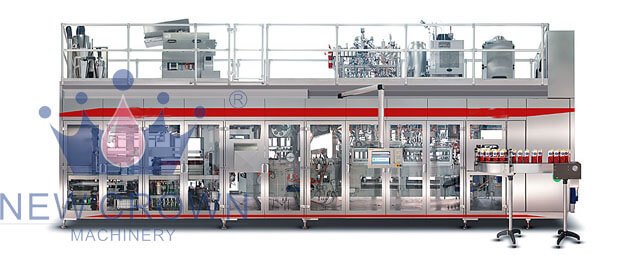

Aseptic Ultra Clean Juice Filling Machine

The aseptic juice bottling machine is used for filling juice into bottled in sanitary environment. 4 in 1 or 5 in 1 filling machine and cap washing tunnel will be applied in production line;

Technical Specifications

| Model: | RCGF12-12-12-4 | RCGF18-18-18-6 | RCGF24-24-24-8 | RCGF32-32-32-10 | RCGF40-40-40-12 | RCGF50-50-50-15 | RCGF60-60-60-15 |

|---|---|---|---|---|---|---|---|

| RCGF12-12-12-12-4 | RCGF18-18-18-18-6 | RCGF24-24-24-24-8 | RCGF32-32-32-32-10 | RCGF40-40-40-40-12 | RCGF50-50-50-50-15 | RCGF60-60-60-60-15 | |

| Capacity: B/H (500ml) | 3000-4000 | 7000-8000 | 10000-12000 | 12000-15000 | 15000-18000 | 20000-22000 | 22000-25000 |

| Bottle shape: | Normal round or square | ||||||

| PET bottle: (mm) | (Bottle Diameter): φ50-φ110mm (Height): 150-310mm Volume: 250ml -2000ml |

||||||

| Cap: | Plastic screw cap | ||||||

| Filling precision: | ≤ ±5mm | ||||||

| Return system | High position tank: 1 set; return tank: 1 set; vacuum pump: 1 set; booster pump: 1 set | ||||||

| Material | Stainless steel 304; touch part: 316 | ||||||

| Power(KW) | 3.0 | 4.0 | 4.2 | 5.2 | 6.2 | 7.5 | 8.5 |

| Gas source pressure: | 6 bar | ||||||

| Rinsing pressure: | 2-2.5 bar | ||||||

| Overall size:(mm) | 1900*1500*2350 | 2250*1650*2350 | 2600*1965*2350 | 2980*2200*2250 | 3880*2200*2250 | 4000*2250*2250 | 5500*3500*2250 |

| 2400*1500*2350 | 2650*1650*2350 | 3000*1965*2350 | 3480*2200*2250 | 4480*2200*2250 | 4500*2250*2250 | 6000*3500*2250 | |

| Weight: (KG) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 | 12000 |

| 3000 | 4000 | 5100 | 7200 | 9000 | 10200 | 12500 | |

| PLC | Mitsubishi / Siemens |

|---|---|

| Touch screen | Mitsubishi / Siemens |

| Contactor | Schneider |

| Rely | Schneider |

| Transducer | Shilin / Mitsubishi / Panasonic |

| Light sensor | Autonics |

| Power | Mingwei |

| Pneumatic parts | Airtac / Festo |

| Stainless steel | ZPSS |

| Motor | Domestic brand / Siemens / ABB |

| Bearing | Domestic brand / NSK |

Description

Product Description:

Aseptic Ultra Clean Juice Filling Machine is used for filling juice into bottled in sanitary environment. 4 in 1 or 5 in 1 filling machine and cap washing tunnel will be applied in production line; 4 in 1 filling machine or 5 in 1 filling machine: 2 or 3 washing part (detergent washing-aseptic water washing-pure water washing), filling part and capping part;

Cap tunnel: caps are washed in closed environment; detergent washing-aseptic water washing-pure water washing;

Features:

– Entire filling machine are totally closed;

– Filling machine can be adjusted the height automatically basing on different height of bottles;

– UV lamps will be installed inside filling machine; it will be turned on after working and before working;

– Air filter system is installed on top of filling machine;

– It is for filling juice into plastic bottle; 330ml-2000ml bottle can be used in same machine (bottle neck must be the same);

– NOTE the touch screen will be apply “Pro-Face”, it can be remote control under internet condition; Once machine program down, we can modify in our factory;

– Except the juice, such filling machine can be used for filling water as well;

– The whole machine structure (all inside parts and outside structure) is totally new designed;

– Sanitary filling head system is of umbrella structure, high filling speed and perfect filling temperature control system and reflux tank system has the function of supplying the material automatically;

– More function can be added basing on requirement;

– High speed performance with less filling head;

– All the spare parts are made in one piece, which will be easy to change;

Applications:

Aseptic Ultra Clean Juice Filling Machine is mainly designed for filling hot temperature liquid; For example juice, tea drinks etc which are made of concentrate juice.

Packaging & Delivery:

All New crown Machines will be packed with high quality plastic film, then put into the wood box increase there is crash and damages.

FAQ:

1, When you can arrange the delivery after customers place the order ?

A: Normally production time is around 30-60days,the exactly depend on what kind of machine you ordered .

2, How long time for installation?

A: According your machines order,we will arrange one or two engineers to your factory,it will take about 1 to 2 weeks.

3, What kind payment be accepted by New crown?

A: We can accept L/C,West union,TT

4, How to install my machines when it arrives?how much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.Customer pay air tickets go and back,accommodation,food,and so on.USD 100/DAY/PERSON

Installation and maintenance:

The machines should have good maintenance twice for 6 months,and for installation, you can get the manual guide from Newcrown, or we can sent our engineers to help you.

Request A Quote

Keep in touch

Fill in your details and we’ll get back to you in no time.