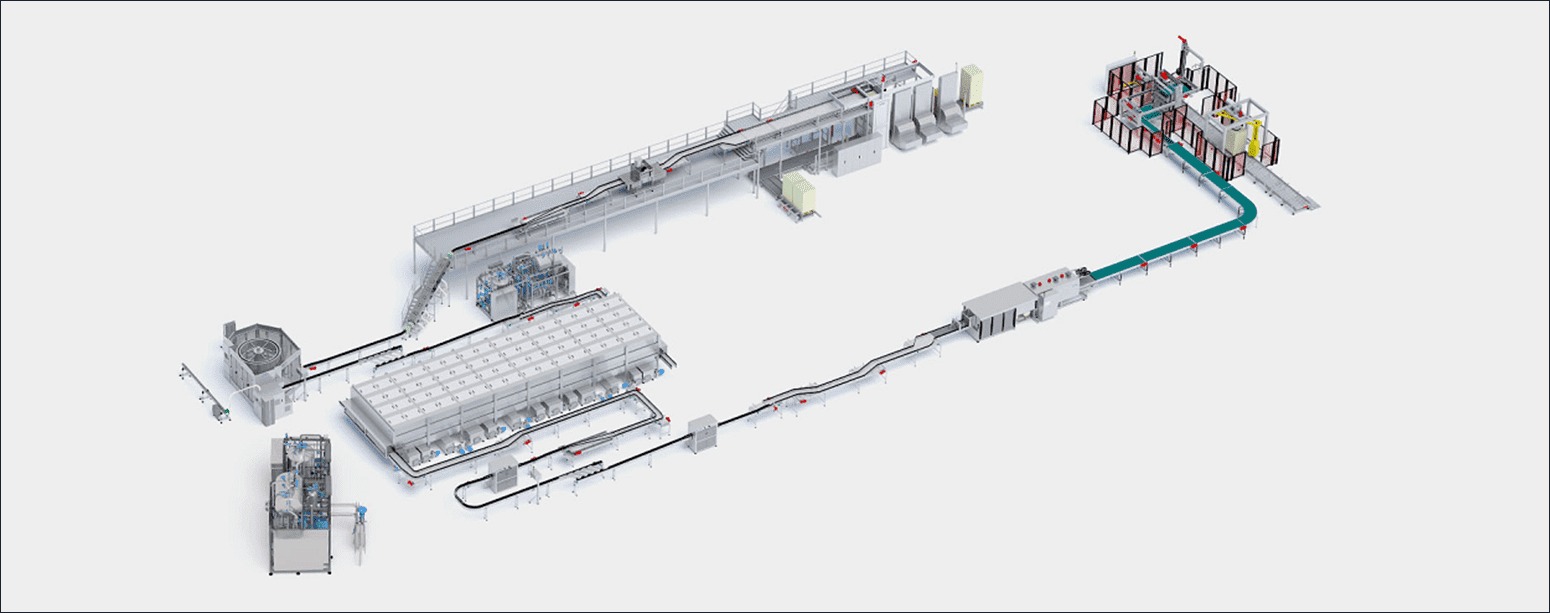

Can CSD Production Line

Can CSD Production Line

Carbonated drink can production line mainly use to produce the beverage like carbonated drink, energy drink, sparkling water, soda and etc in aluminium can and tin can.

Complete Customization

Each production line can be fully customized to realize customers' dreams according to their conditions and product characteristics.

Efficient Production

High-speed automatic filling production line features with stable performance, safe design, simple operation, high productivity and low cost.

Multiple Purpose

Each line suits a variety of special-shaped cans and industries and it is convenient and quick to change the can type.

Optional Function

In addition to the existing functions, every production line has professionals to do more equipped with other machines.

TECHNOLOGY SHOW

Our turnkey can lines have high production efficiency thanks to the latest technology and scientific layout.

Beverage Mixer Large capacity with high--efficiency mixing.

Liquid Level Tester Non-contact detection, fast detection speed and high precision.

Vacuum Detector Good testing results with lines running.

Post Packaging Machine High automation for secondary packaging of various cans.

Palletizer Full-auto, intelligent managing and saves labours.

De-palletizer Automatic depalletizing of the whole stack of empty cans.

Pasteurization Sterilize Tunnel Latest technology integrates sterilization and cooling.

Can washer Clean turn-out cans with high production efficiency.

Filling Seaming Machine Overall design for canned beverage industry.

Water Treatment System

Water treatment system has purifiers to produce pure water and mineral water meeting the drinking water standard, which has a treatment capacity of up to 100,000L/H.

Beverage Processing System

The beverage processing system is a pre-treatment complete set of different juice drinks carbonated drink beverages. And all kinds of raw materials are extracted or dissolved here according to the predetermined process parameters.

Can De-palletizer

The automatic depalletizer is mainly suitable for the automatic depalletizing of the whole stack of empty cans, which can save a lot of labour and improve production capacity.

Beer Can Filling Seaming Machine

The overall design of filling and seaming machine is suitable for the filling and sealing of steam cans with high speed, smooth running and good sealing quality.

Can Spray Warming Tunnel

The bottle warming machine is designed and manufactured for the production line of carbonated beverages. It heats the bottle body with circulating hot water, which is necessary for line’s running.

Packing System

Post packaging machine with high automation, reliable control, simple operation is widely used in water, juice, carbonated drink, oil, wine, chemical, medical and other industries.

Conveyor System

The conveyor system with a capacity of up to 48,000bph includes bottle warmer, bottle cooler, pasteurization spray tunnel, chain conveyor and case conveyor.

Palletizer

The automatic palletizer can put different products in a fixed order and stack them on the pallet automatically, which is easy to master and saves labour costs.

Detect System

The cans visual inspection system has a good testing capacity and can detect cans’ appearance at high speed while the production line keeps running.

Get your customized high-efficiency production line!

FAVOURABLE REVIEWS

NEWCROWN has made good cooperations with many overseas customers and they are happy to share experience about our turnkey lines.