PP PE Bottle Milk Filling Machine

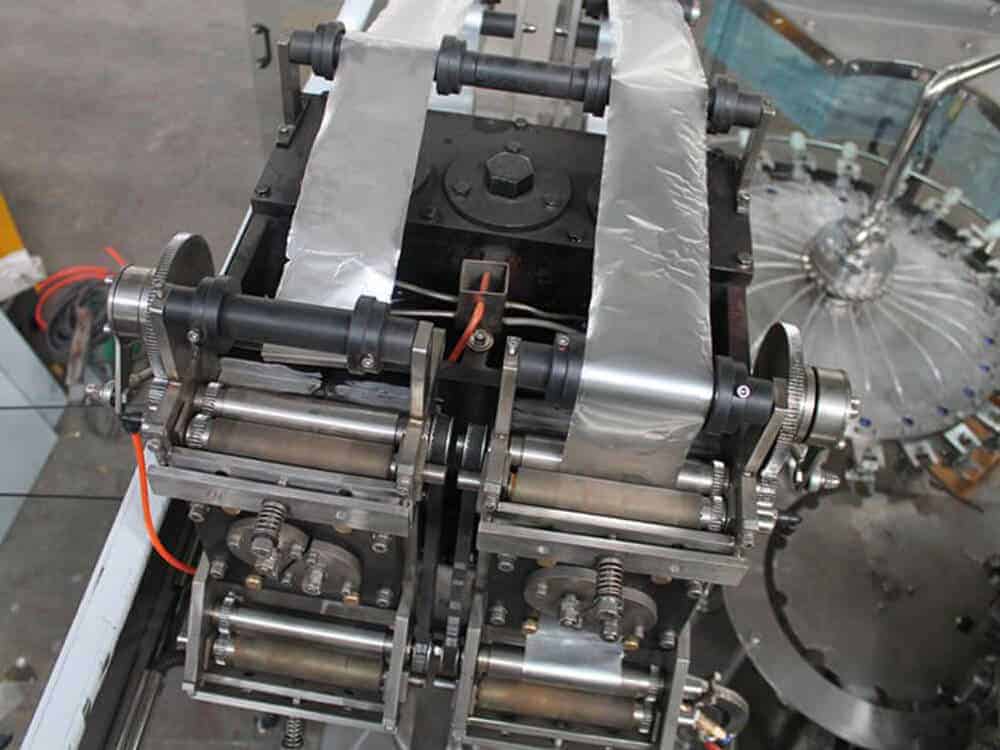

PP PE plastic bottle milk filling bottling machine is for fresh and powder milk filling. can apply both to plastic and glass bottle. with aluminum foil sealing.

Technical Specifications

| Model | YFM - 24 - 24 - 8 |

|---|---|

| Production capacity (500ml) b / h | 10000 |

| Suitable bottle diameter mm | 50 - 100 |

| Suitable bottle height mm | 120 - 320 |

| Suitable bottle cap | All |

| Pressure Mpa | 0 - 0.7 |

| Bulking accuracy (liquid level which you customized) mm | less than 5 |

| Filling valve | 24 |

| Washing valve | 24 |

| Capping valve | 8 |

| Power kw | 5.2 |

| Weight kg | 4500 |

| Dimensions L * W * H mm | 2900 * 2200 * 2250 |

Description

Product Description:

The PP PE Bottle Milk Filling Machine is mainly used in the veverage filling perations .The three fuctions of bottle washing / filling / capping are composed in one body of the machine. The whole process is automatic . The machine is used in filling juices , mineral water and purified water in bottles made of polyester and plastics .The humanized design excellent performance milk filling machine can also be used in hot filling if being installed with temperature controlling device . The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles, The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted .

The advanced OMRON programmed PLC controller is adopted to control the machine to run automatically while a transducer is used in the bottle – entering chains to adjust speeds and corrdinated with the transducer of the mian machine to make the operations of moving bottle forward steadily and reliably . It is convenient to operate with higher automation. because every part of the machine is inspected to run with photo electricity .

On the bases , the filling part of the humanized design excellent performance milk filling machine can be changed into filling methods of lower vacuum. The filling category of lower vacuum is applicable in glass bottles , filling alcohol , soy , carbonated , tomato sauce , etc . The aluminum theft proof cap and platic cap can be adopted . The machine is an idea – preferred equipment for beverage makers.

Advantages:

The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted .

The advanced OMRON programmed PLC controller is adopted to control the machine to run automatically while a transducer is used in the bottle – entering chains to adjust speeds and corrdinated with the transducer of the mian machine to make the operations of moving bottle forward steadily and reliably .

It is convenient to operate with higher automation because every part of the machine is inspected to run with photo electricity .

Application:

PP PE plastic bottle milk filling bottling machine can also be used in hot filling if being installed with temperature controlling device . The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

Packaging & Delivery:

All New crown Machines will be packed with high quality plastic film, then put into the wood box increase there is crash and damages.

FAQ:

1, When you can arrange the delivery after customers place the order ?

A: Normally production time is around 30-60days,the exactly depend on what kind of machine you ordered .

2, How long time for installation?

A: According your machines order,we will arrange one or two engineers to your factory,it will take about 1 to 2 weeks.

3, What kind payment be accepted by New crown?

A: We can accept L/C,West union,TT

4, How to install my machines when it arrives?how much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.Customer pay air tickets go and back,accommodation,food,and so on.USD 100/DAY/PERSON

Installation and maintenance:

The machines should have good maintenance twice for 6 months,and for installation, you can get the manual guide from Newcrown, or we can sent our engineers to help you.

Request A Quote

Keep in touch

Fill in your details and we’ll get back to you in no time.