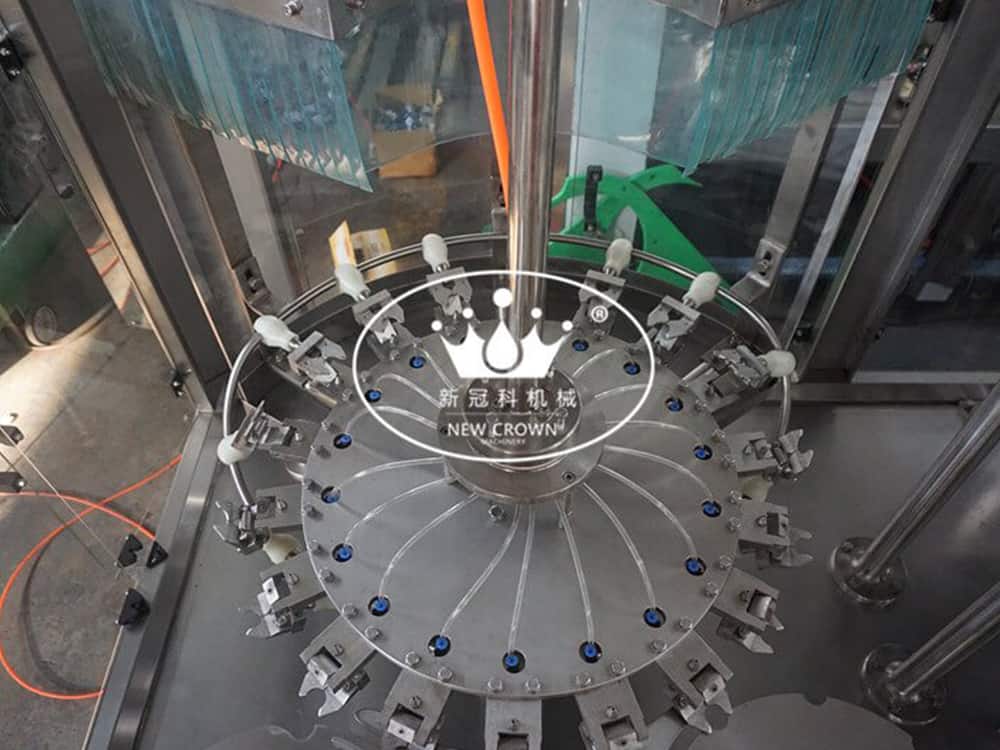

Basil Seed Juice Filling Machine

Monoblock 4 in 1 basil seed juice and pulp juice filling machine for both PET bottle and glass bottle is using hot filling to filling to fill juice and piston filling to fill inside pulp or basil seeds.

Technical Specifications

| Model | RCGFB12-12-12-4 | RCGFB18-18-18-6 | RCGFB24-24-24-8 | RCGFB32-32-32-10 | RCGFB40-40-40-12 | RCGFB50-50-50-15 |

|---|---|---|---|---|---|---|

| Bottle Washing Head | 16 | 18 | 24 | 32 | 40 | 50 |

| Plup Filling Head | 12 | 12 | 18 | 24 | 32 | 40 |

| Juice Filling Head | 16 | 18 | 24 | 32 | 40 | 50 |

| Cap Screwing Head | 6 | 6 | 8 | 10 | 12 | 15 |

| Rated Production Capacity | 4000BPH | 6000BPH | 8000BPH | 12000BPH | 15000BPH | 20000BPH |

| Installed Capacity | 3.8KW | 4.3KW | 6.5KW | 8.7KW | 9.5KW | 12KW |

| Overall Size(MM) | 3050*2000*2400 | 3170*2070*2400 | 4070*2350*2400 | 5100*2600*2400 | 6250*3050*2400 | 7500*3900*2400 |

Description

Product Description:

Basil Seed Juice Filling Machine is Monoblock 4 in 1. basil seed juice and pulp juice filling machine for both PET bottle and glass bottle is using hot filling to filling to fill juice and piston filling to fill inside pulp or basil seeds.All the machine part which contact with liquid is high quality stainless steel 304. The relative fittings are from international famous brand.

The automatic Monoblock 4 in 1 basil seed juice and pulp juice filling machine was equipped with suspension type air conveyor and frequency control of motor speed.

This machine is comprised of rinsing, filling1, filling2 and capping system. Rinsing: grip the bottle neck, rotate filling plate, inverse bottle; internal rinsing and external spraying make bottles be cleaned completely. Filling: hot filling with holding bottle neck; the special back flow type of the filling valve can avoid leakage after filling and also control liquid level accurately. Capping: magnetic torque bottle holding type can minimize the cap damage rate and make the capping performance the best.

This machine owns the reasonable, stable and safe design. Under the condition that the bottle neck size is the same, only the output star wheel needs to be changed if bottles are different. It improves the efficiency a lot.

Advantages:

– The machine is 4 in 1 filling machine, including bottle rinsing, juice filling and bottle capping(2 type cap);

– Filling machine can be adjusted the height automatically basing on different height of bottles;

– It is for filling juice into plastic bottle; 330ml-2000ml bottle can be used in same machine (bottle neck must be the same);

– NOTE the touch screen will be apply “Pro-Face”, it can be remote control under internet condition; Once machine program down, we can modify in our factory;

– There is return system, including high position tank, return tank, vacuum pump and pump; For return juice to sterilizing machine;

– Except the juice, such filling machine can be used for filling water as well;

– The whole machine structure (all inside parts and outside structure) is totally new designed;

– Sanitary filling head system is of umbrella structure, high filling speed and perfect filling temperature control system and reflux tank system has the function of supplying the material automatically;

– More function can be added basing on requirement;

– High speed performance with less filling head;

– All the spare parts are made in one piece, which will be easy to change;

Application:

Basil Seed Juice Filling Machine is mainly designed for filling hot temperature liquid; For example juice, tea drinks etc which are made of concentrate juice.

Packaging & Delivery:

All New crown Machines will be packed with high quality plastic film, then put into the wood box increase there is crash and damages.

FAQ:

1, When you can arrange the delivery after customers place the order ?

A: Normally production time is around 30-60days,the exactly depend on what kind of machine you ordered .

2, How long time for installation?

A: According your machines order,we will arrange one or two engineers to your factory,it will take about 1 to 2 weeks.

3, What kind payment be accepted by New crown?

A: We can accept L/C,West union,TT

4, How to install my machines when it arrives?how much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.Customer pay air tickets go and back,accommodation,food,and so on.USD 100/DAY/PERSON

Installation and maintenance:

The machines should have good maintenance twice for 6 months,and for installation, you can get the manual guide from Newcrown, or we can sent our engineers to help you.

Request A Quote

Keep in touch

Fill in your details and we’ll get back to you in no time.